Custom product design is a regular service provided by MINIB for larger projects. Even in the case of smaller projects or piece production, it can be often justified.

The MINIB company has extensive experience in the design of custom products, approximately half of the delivered products have an atypical design. This also corresponds to the organization of the production process, which works equally efficiently in the case of standard as well as custom products.

Samples of custom products can be found at the bottom of the page.

Why custom design?

There are many reasons to consider a custom designed product. Below are examples of the most common reasons for a specific product design.

Even in cases where the standard product is completely satisfactory, the cooperation of the architect, designer or installation company with the manufacturer helps to ensure the smooth progress of the project. Especially in the case of larger construction projects, the financial, organizational and time benefits of close cooperation are significant.

Modern architectural and interior design

Contemporary architectural designs make full use of the most modern materials and production technologies. An architectural or interior design is much less limited by construction or production limits and thus gives the opportunity to create unique buildings or interiors. The MINIB company goes with this trend and its customized product design enables the realization of modern buildings without compromises in accordance with the creative intentions of the architect.

Limited building options

A construction project is often limited by the conflicting requirements and needs of individual components of the building and thus has to approach compromise solutions, which often mean an extension of the time of construction work, an increase in price and other construction complications.

In these cases, custom product design can adapt the product to the project’s needs and provide more space to address the conflicting needs of other components of the building.

Typical limitations are the dimensions of the product, the connection of the product to distribution systems, performance parameters, installation and anchoring, and the like.

Changes in the project

Construction projects are highly complex and time-consuming. The parameters and conditions of the project are constantly changing from the preparatory phase to the handover of the finished building.

Tailor-made product design or modification of the designed product is usually the optimal way to minimize the impact of the changing environment on the project.

Typical changes in the project are a request to change the supplier, an increase in project costs, deficiencies in the planning of construction implementation, changes forced by the investor or other changes forced by related components of the construction.

Cost optimization

Of course, the design of a customized product entails costs associated with the design of a new or modification of a standard product. These are mainly the costs of the product design itself and const of the prototype to verify the functionality of the design.

This increase is, in most cases, amply compensated by the reduction in costs due to easier and faster installation of the product. In the case of a larger number of products of the same type, the costs associated with the design are negligible in the total amount.

Optimizing the product in cooperation with the designer and the installation company often leads to a saving of 1/4 - 1/2 of the installation time compared to a standard product.

Advantages and disadvantages of an atypical solution

Pros

- the appearance of the product is completely aligned with the interior and thus forms an integral part of it

- elimination of conflicts with other elements of the building

- quick and cheap installation thanks to product optimization in production

- a decrease in the total cost of purchasing and installing the product

- the cooperation of the actors concerned eliminates ambiguities in the project, the concrete solution of which is postponed to the construction and installation phase

Cons

- in the case of smaller quantities (units or small tens of pieces), it has a slight effect on increasing the price of the product

What is possible?

When designing a specific product, we are limited by nothing but the laws of physics. However, a completely atypical product is not always needed. Sometimes just adjusting the size is enough to make the build go smoothly.

Change of format

In the case of length dimensions, this change is very easy to make without affecting the function of the product. Logistical and production limitations determine the maximum length of one piece to approx. 3000 mm. However, the individual pieces can be easily connected on the construction site into a functionally and visually uniform unit.

In the case of a change in height or width, this is a deeper intervention in the structure of the product, which can affect its function. Especially in the case of products based on natural convection, a change in dimensions can strongly affect their function. Thanks to our experience and measurements of the behavior of our products in atypical conditions, we are able to offer you a suitable solution even in these cases.

Performance enhancement

Increasing performance is one of the most frequent requests of our customers, which we are able to fulfill easily within certain limits.

Since our products are also optimized for the final price, their potential is not 100% used in standard production. For most products, we are able to increase performance by 10-15% with reasonable cost increases through structural modifications.

If the performance requirement is beyond the capabilities of the given product, we can offer you a specific product designed to fit your needs.

Atypical shape

Most of our products can be manufactured in any curvature according to your request. The limiting parameter here is the appearance of the cover grille, which is why we typically offer curvature up to a radius of approx. 600 mm. Of course, it is also possible to create an“infinite” sequence of several pieces connected to each other to create the shape of any curvature.

A completely atypical product

In rare cases, the product requirements are so specific that it is more advantageous to design it from scratch.

Although the development of a brand new product is usually a time- and financial-intensive activity, the company’s rich experience in developing atypical solutions allows MINIB to carry out all development steps quickly and efficiently. The result is a significant simplification of the project, installation work and overall cost savings.

Examples of atypical solutions

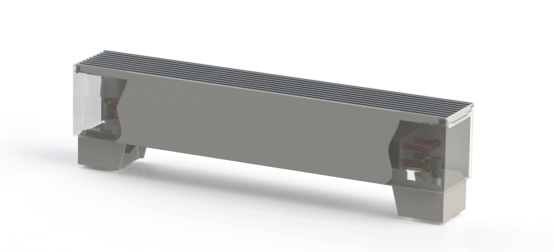

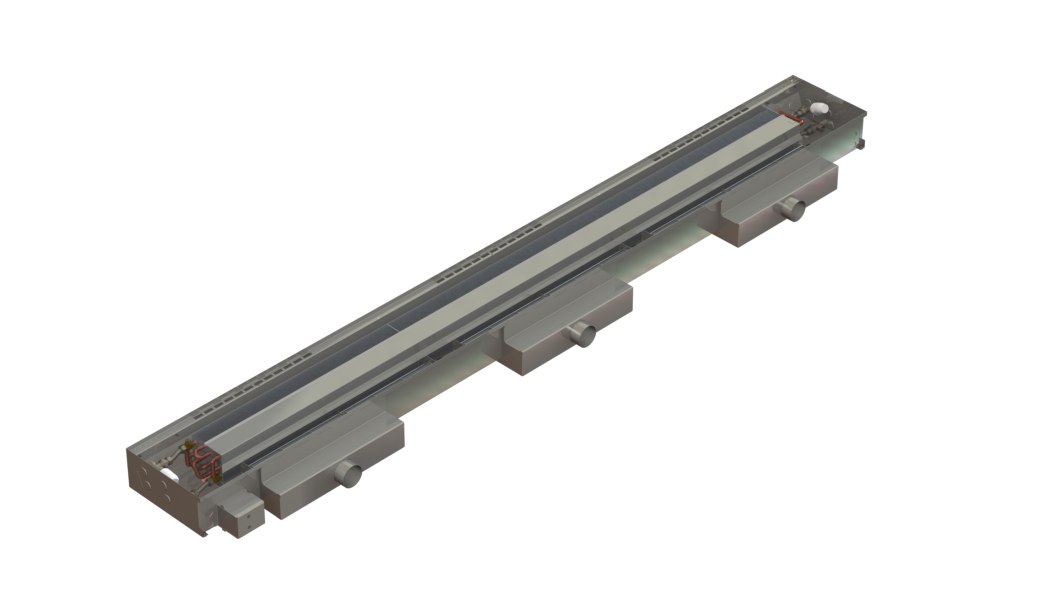

| Continuous heat exchanger — independent convector for serial connection |

|---|

|

Existing distribution systems may in some cases force a non-standard way of connection, for example if the inlet and outlet are in a single place or the inlet is in one place and the outlet is in another place.

Connecting the convectors behind each other in series is a solution that eliminates the need to change the wiring, which can be applied to all types of our products.

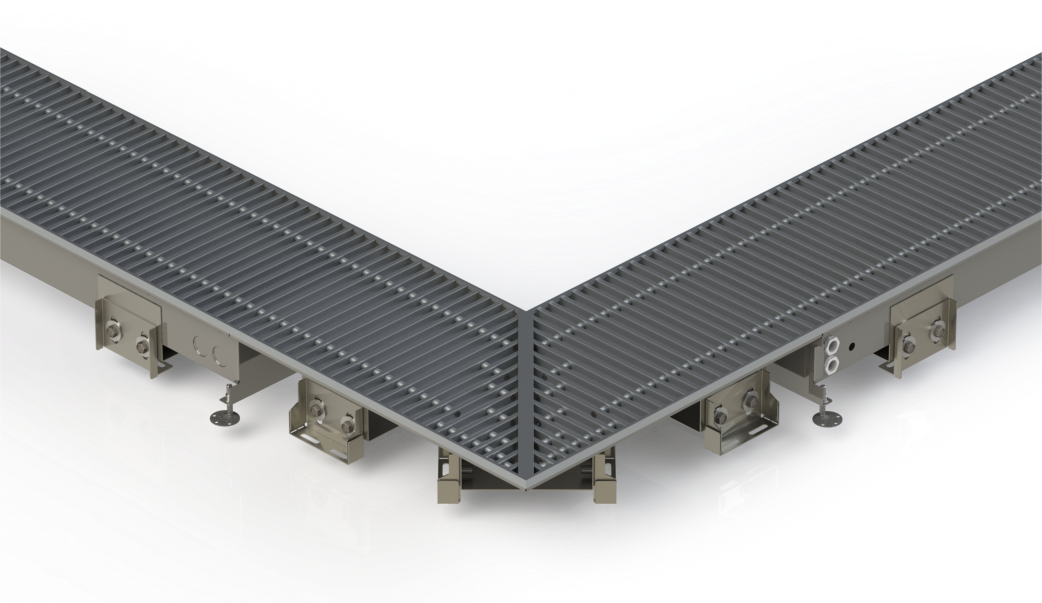

| Joint of floor convectors |

|---|

|

The joints of the convectors enable the visually uniform installation of floor units in any length. A joint can include straight, angular and arc segments.

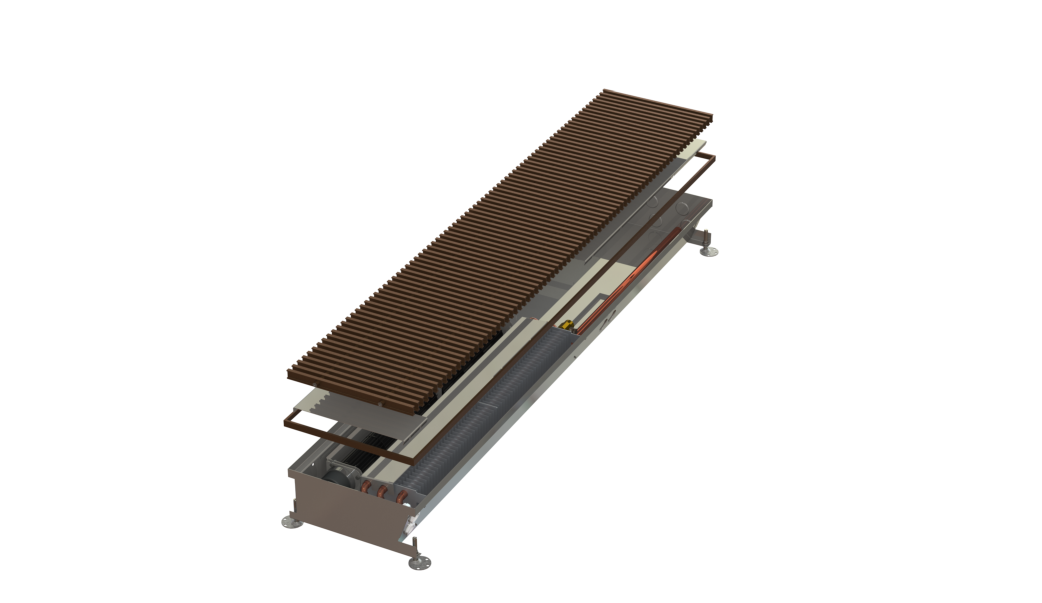

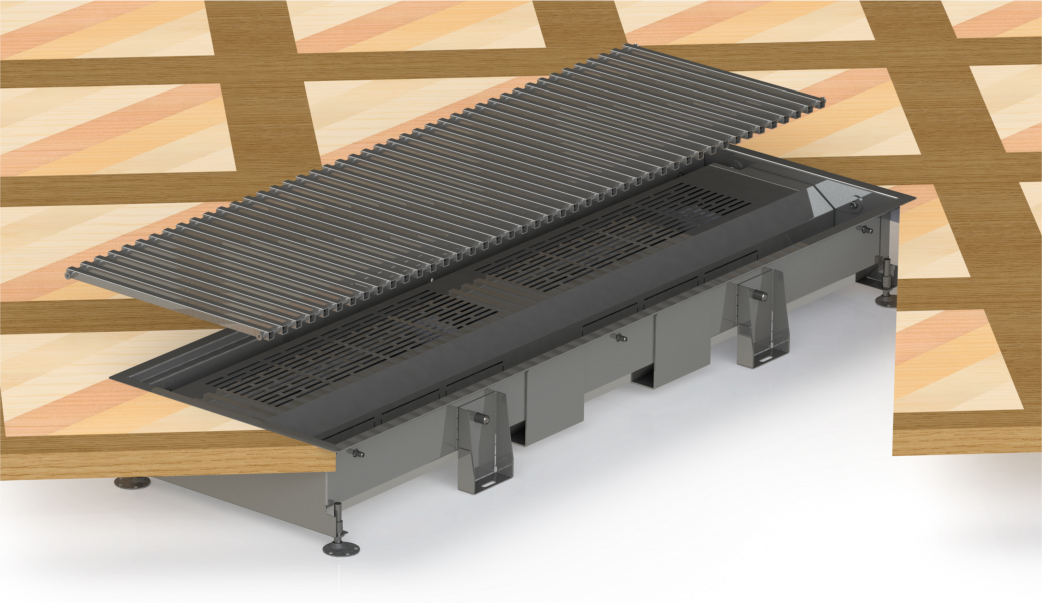

| Extended trough/body of convector |

|---|

|

Extending the trough/body is suitable in cases where the interior requires specific length without the need to increase its performance. The cost savings of the extended body is significant because it does not include a significant part of heat exchanger extension.

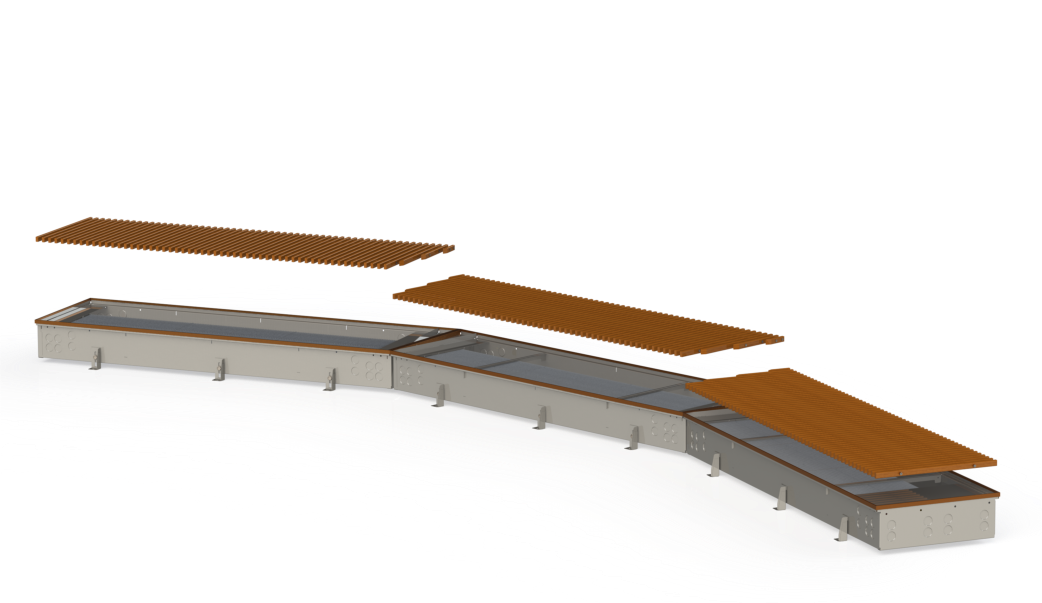

| Arch and curved arch |

|---|

|

If the floor plan of the room is not rectangular, it is necessary to adapt the shape of the body to the shape of the room. In simpler cases, a bent arch will suffice, more demanding structures may require more complex body curves.

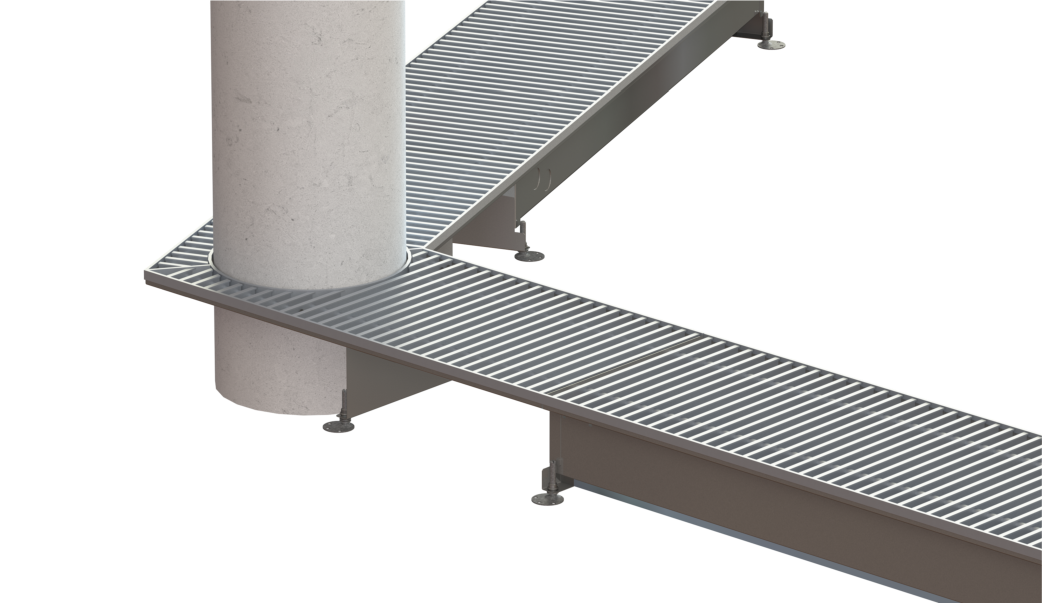

| Pillar embedded in lattice |

|---|

|

Strict appearance requirements may require the incorporation of building elements into the appearance of the body, such as the passage of the body through supporting pillars.

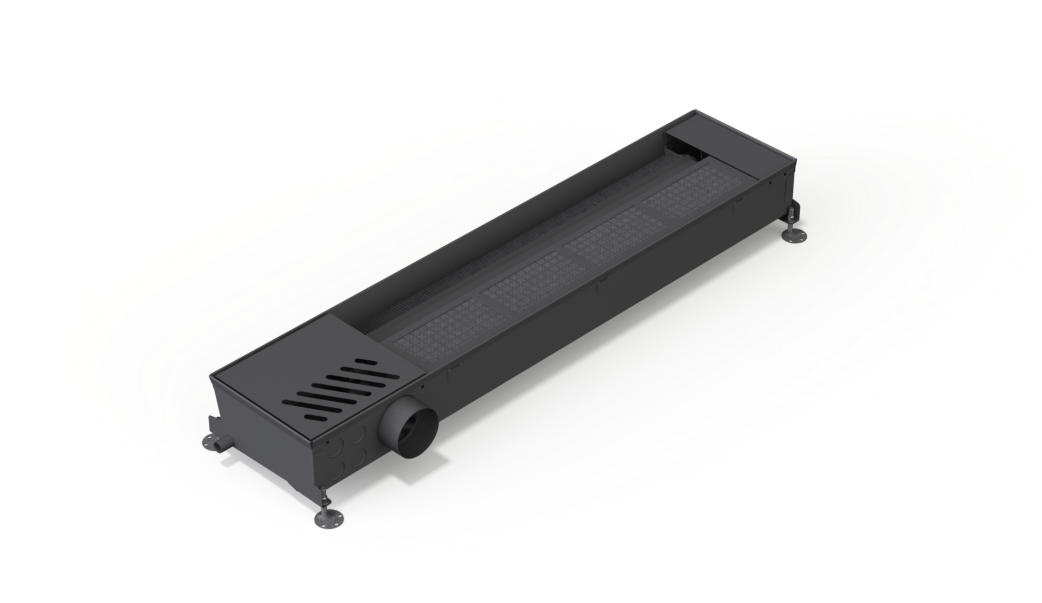

| Convector air outlet |

|---|

|

|

The air outlet integrated in the body of the convector is an elegant way of supplying and extracting air from the room, which offers an aesthetic and space-saving solution.

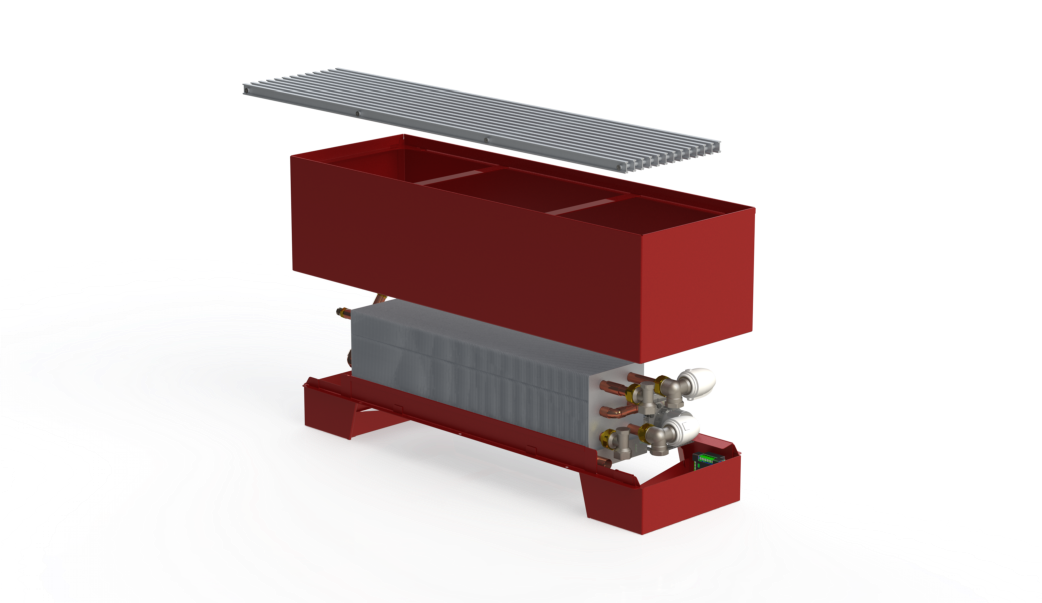

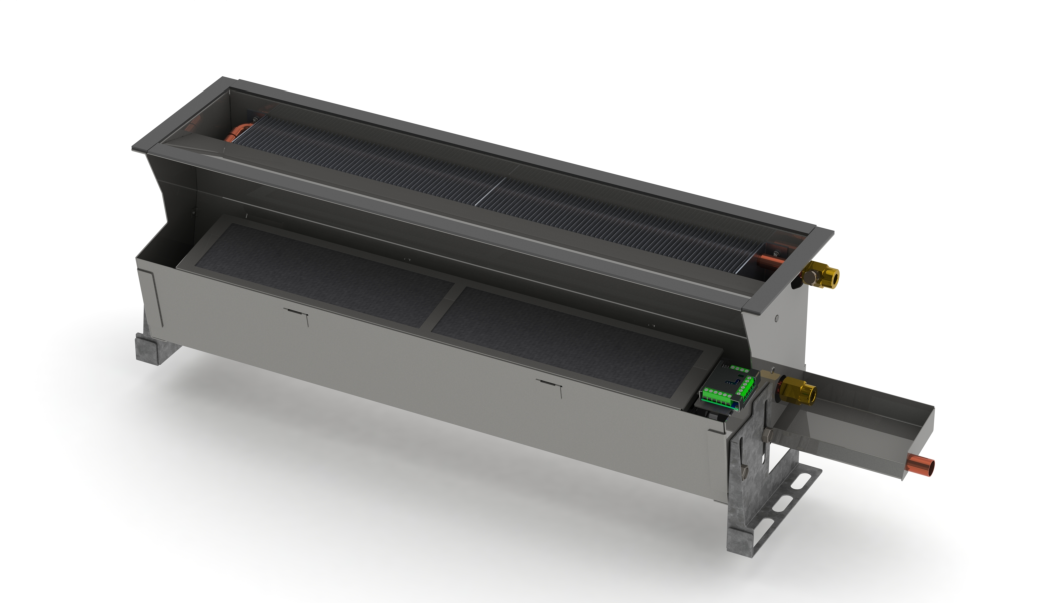

| Powerful stand-alone convector for production facilities |

|---|

|

Industrial installations, such as production halls, emphasize different body parameters than residential projects. Emphasis is placed especially on the efficiency, performance and price of the product.

| Height adjustable stainless steel frame |

|---|

|

The retrofit of heating elements in historic buildings, such as castles, museums or government buildings, places high demands on the appearance of the element and, due to the inaccuracies of the construction, also on the variability of the installation.

| Convector for built-in | |

|---|---|

|

Installation in existing cladding does not require covering the convector body. Adapting the shape of the body to the building simplifies installation and optimizes the use of space. |